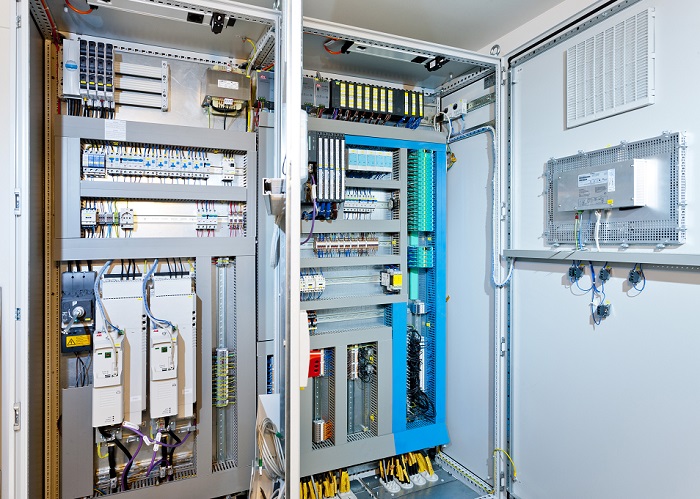

Burner Management System

The advanced process reliability of its combustion technologies is a top priority for DUMAG to ensure largely trouble-free and safe operation of our customers’ production systems.

The DUMAG Burner Management System (BMS) meets all legal requirements to guarantee a no-risk combustion process. In addition to ongoing recording and evaluation of all the critical parameters in continuous operation, safety also includes reliable start-up and shut-down of the firing unit. The monitoring of flame stability, a safety-oriented air mass ratio control including locking of the fuel supply, plus additional residual oxygen measurement are essential features of a modern Burner Management System designed to meet the demands and challenges of the future

Advantages of the DUMAG® BMS at a glance:

- Certified fail-safe software modules (2006/42/EG, IEC 62061, ISO 13849)

- Automatic start sequences and safe stop sequences

- Adjustment of parameters to various fuels

- User-friendly visualisation

The integrated communication interface (PROFINET/PROFIBUS) provides the operator with the essential information about the condition and status of the plant and important messages about any deviations. It also allows diagnosis – where required – to ensure maximum uptime of the plant.

In the event that pre-defined safety limits are exceeded, the BMS fully automatically returns the incineration system to safe state in line with the relevant standards.

Drawing on its many years of experience with combustion processes and its in-house expertise, DUMAG is able to provide its customers with tailor-made solutions, planning services and documentation for virtually any task. In order to support the most time- and cost-optimised implementation of the BMS possible, DUMAG relies on type-tested and certified modules that are developed in-house or on modules that have been tried and tested in practical use.

- Recording and archiving of trends

- Access passwords for program levels

- Communication with higher-level control units (DCS)

- Dynamic maintenance request

- Optional 24/7 support available

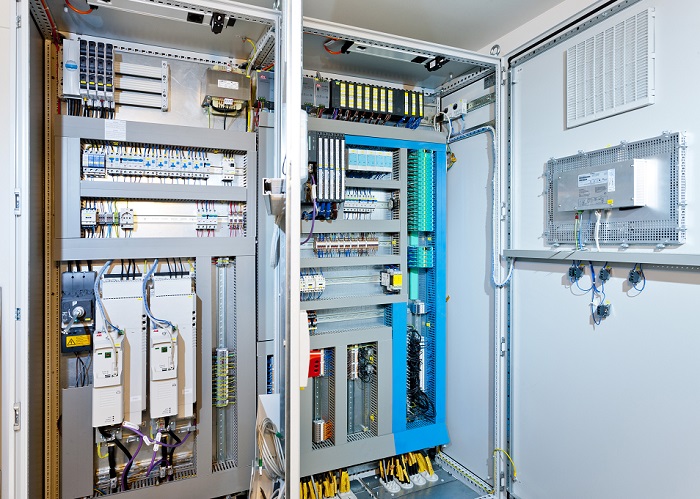

Burner Management System

The advanced process reliability of its combustion technologies is a top priority for DUMAG to ensure largely trouble-free and safe operation of our customers’ production systems.

The DUMAG Burner Management System (BMS) meets all legal requirements to guarantee a no-risk combustion process. In addition to ongoing recording and evaluation of all the critical parameters in continuous operation, safety also includes reliable start-up and shut-down of the firing unit. The monitoring of flame stability, a safety-oriented air mass ratio control including locking of the fuel supply, plus additional residual oxygen measurement are essential features of a modern Burner Management System designed to meet the demands and challenges of the future

The integrated communication interface (PROFINET/PROFIBUS) provides the operator with the essential information about the condition and status of the plant and important messages about any deviations. It also allows diagnosis – where required – to ensure maximum uptime of the plant.

In the event that pre-defined safety limits are exceeded, the BMS fully automatically returns the incineration system to safe state in line with the relevant standards.

Drawing on its many years of experience with combustion processes and its in-house expertise, DUMAG is able to provide its customers with tailor-made solutions, planning services and documentation for virtually any task. In order to support the most time- and cost-optimised implementation of the BMS possible, DUMAG relies on type-tested and certified modules that are developed in-house or on modules that have been tried and tested in practical use.

Advantages of the DUMAG® BMS:

- Certified fail-safe software modules (2006/42/EG, IEC 62061, ISO 13849)

- Automatic start sequences and safe stop sequences

- Adjustment of parameters to various fuels

- User-friendly visualisation

- Recording and archiving of trends

- Access passwords for program levels

- Communication with higher-level control units (DCS)

- Dynamic maintenance request

- Optional 24/7 support available