1930

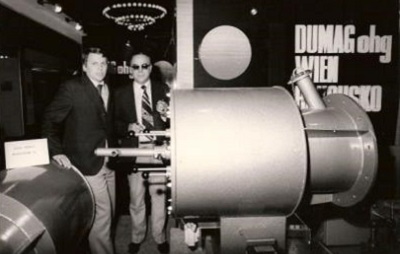

DUMAG founded

1966

Business graduate Adalbert Marko, owner of the trading company DUMAG OHG, has set up the ambitious plan of a production company for ultrasonic nozzles and buys the American patent “Astrosonics”, an utrasonic nozzle for the finest atomization of liquids. After brief trials, the fine atomization of the ultrasonic nozzle which atomizes fuel to the principle of Hartmanns’s gererator is recognized, but it cannot be used for industrial purposes.

1967 – 1971

First attempts towards the industrial application of the DUMAG nozzle and continuous further development.

1971 – 1976

Further developement of the ultrasonic nozzle until it is ready for series production, new inventions for the nozzle and expired patents for this, the DUMAG® ultrasonic nozzle of the 08 series is launched. Highlight: the atomization of liquids with a high proportion of solids and suitable for large solid particles. A development that was necessary for getting started with the incineration of liquid waste.

1972

The conception is radically changed after Heinz Haberfelner took over control over technical management. The ultrasonic nozzle and the burner system developed based on it attained a resounding success, especially for highly viscous heavy oils and contaminated waste materials. Several patents are granted.

1973 & 1974

Together with Bayer Leverkusen and the Technical University of Aachen, further developments of the ultrasonic nozzle for atomizing liquid sulfur for the production of sulfuric acid have been made.

1975

The invented ultrasonic atomization with a variable type of spraying allows flames to be shaped. This invention is the basis for today’s universal and flexible use of industrial burners.

1976

The development of gas lances as a slide-in charging pipe or sleeve tube inserted into the burner enhances these burners to act as multi-functional burners for burning gaseous and liquid fuels in conjunction with gaseous and liquid waste materials.

From 1977

1977

Development of sulfur spraying using the ultrasonic nozzle in cooperation with Davy McKee and Technical University of Karlsruhe. Successful applications in the production of sulfuric acid are the basis for the development of DUMAG sulfur burners.

1980

First successful use of a burner having a pre-combustion chamber for gas/solvent/water in a commercially available thermal oil burner.

1985

Based on several research grants, a Low-NOx burner constructed as a three-flow burner with internal flue gas recirculation is developed. These burners were successfully used from 2005.

From 1985 up to now

1988

Development of a melting burner with a movable burner lance for melting slag in a rotary kiln.

Since 1989

Creation of an extensive DUMAG database with approx. 1000 combustible liquid and gaseous waste materials.

1995

Ongoing development of the COMOFF system. This is a modular system that may be used in any combination applying the DUMAG elements nozzle/gun/burner/RVT/pre-combustion chamber/additional lances for the combined combustion of gaseous and liquid fuels / gaseous and liquid waste materials / gaseous and liquid alternative fuels as well as for offgases, exhaust air etc.

2000 – 2008

In cooperation with the TU Vienna (support from FFG – The Austrian Research Promotion Agency), several years of development of LowNOx burner series for boilers.

2006 – 2008

Revision of the ultrasonic nozzle and new launch of the DUMAG® ultrasonic nozzle series 08 with Ø from 12 to 139 mm with improved flame adjustment, more stable flame, larger control range, etc.

2006

Heinz Haberfelner resumes work in development and technical management. Development of the new ultrasonic nozzle series. Significant improvement of control range, flame stability, reduction of sensitivity to erosion, reduction in pressurized air throughput. Simple change of flame shape from jet shape to tulip shape or vice versa and thus simplified start-up.

2007

Development of a gas ring distributor RVT as a burner extension. This development resulted from the need to be able to co-incinerate major amounts of lean gas, offgases and the like.

2008 – 2014

Extensive work on the development of LowNOx burners for combustion chambers and boilers for natural gas and fuel oil. (in cooperation with FFG).

2009 – 2011

Development of large nozzles (supported by FFG) up to a Ø of 139 mm. Use of the nozzles in burners in the production of sulfuric acid, e.g. Throughput of liquid sulfur up to 28 t/h, burner power 70 MW.

2008 – 2020

Forming of an in-house burner management system with TÜV-certified components.

2010

Invention of an oxygen ultrasonic nozzle for heating oil (supported by FFG) and alternative oils to save energy in melting and annealing processes in the metal industry.

Invention and further development of the CSB burner, a burner with a high control range of up to 1:50 at a very low gas inlet pressure. This enables the cost-saving development of tank ventilation systems.

2011

Development of a lance burner with ultrasonic nozzles for liquid or gases, which can be quickly switched from on type of gas or liquid to another liquid or gaseous medium.

2012

Foundation of CTP-DUMAG GmbH. Robert Schröger and Heinz Haberfelner take over DUMAG’s immaterial assets together with CTP.

From 2014

Licensing and engineering for combustion chambers for liquid and gaseous alternative substances.

From 2015

Licenses and engineering for the DUO System. Use of up to 30 DUMAG lances in the burner or in the combustion chamber. Combustion chamber power up to 54 MW.

2018

Acquisition of all company shares by the management, corporate name change to DUMAG GmbH.

2020

Development of the ultrasonic nozzle for the use as a gas nozzle with the advantage of the adjustable flame shape and stable combustion behavior.