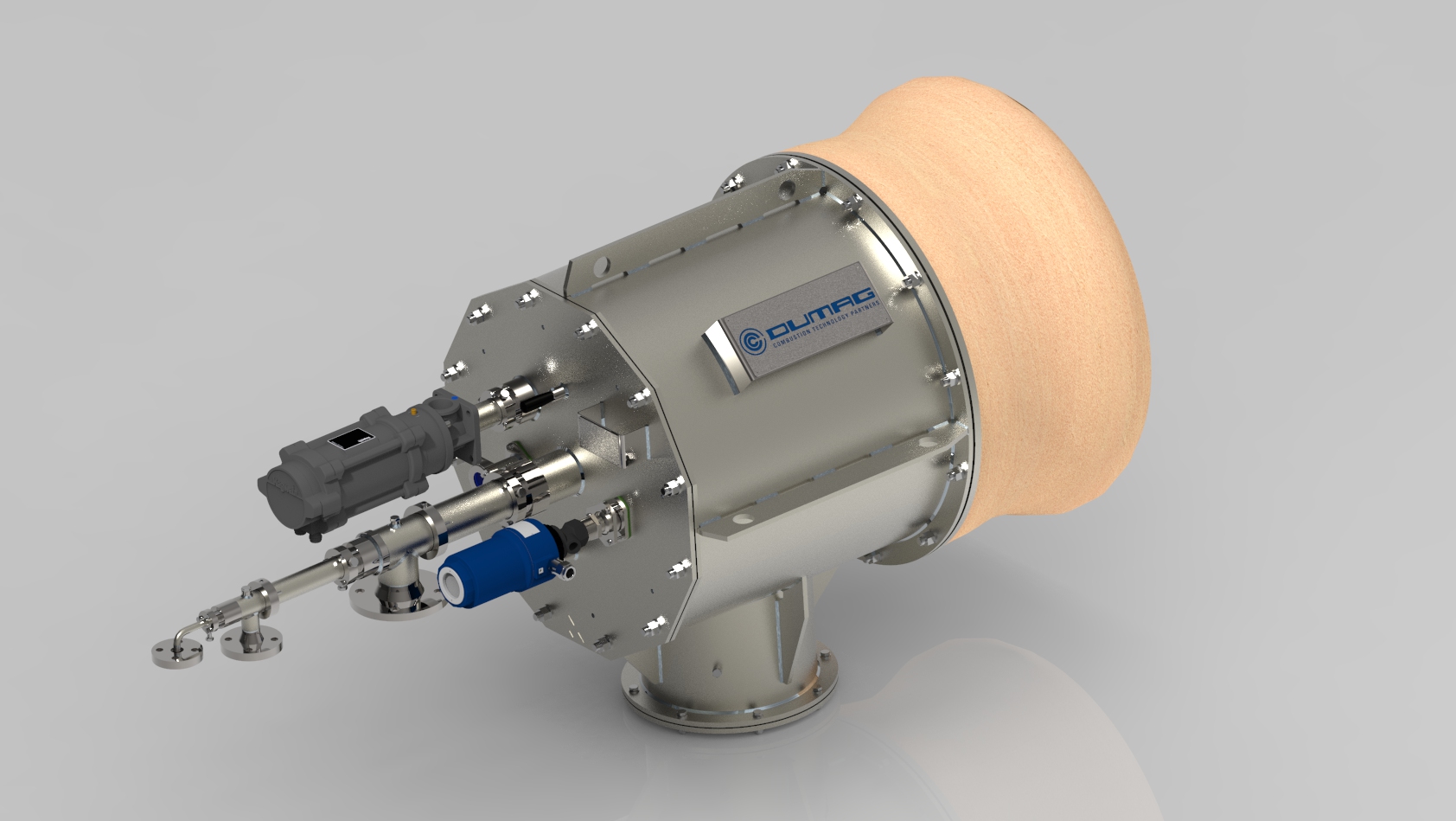

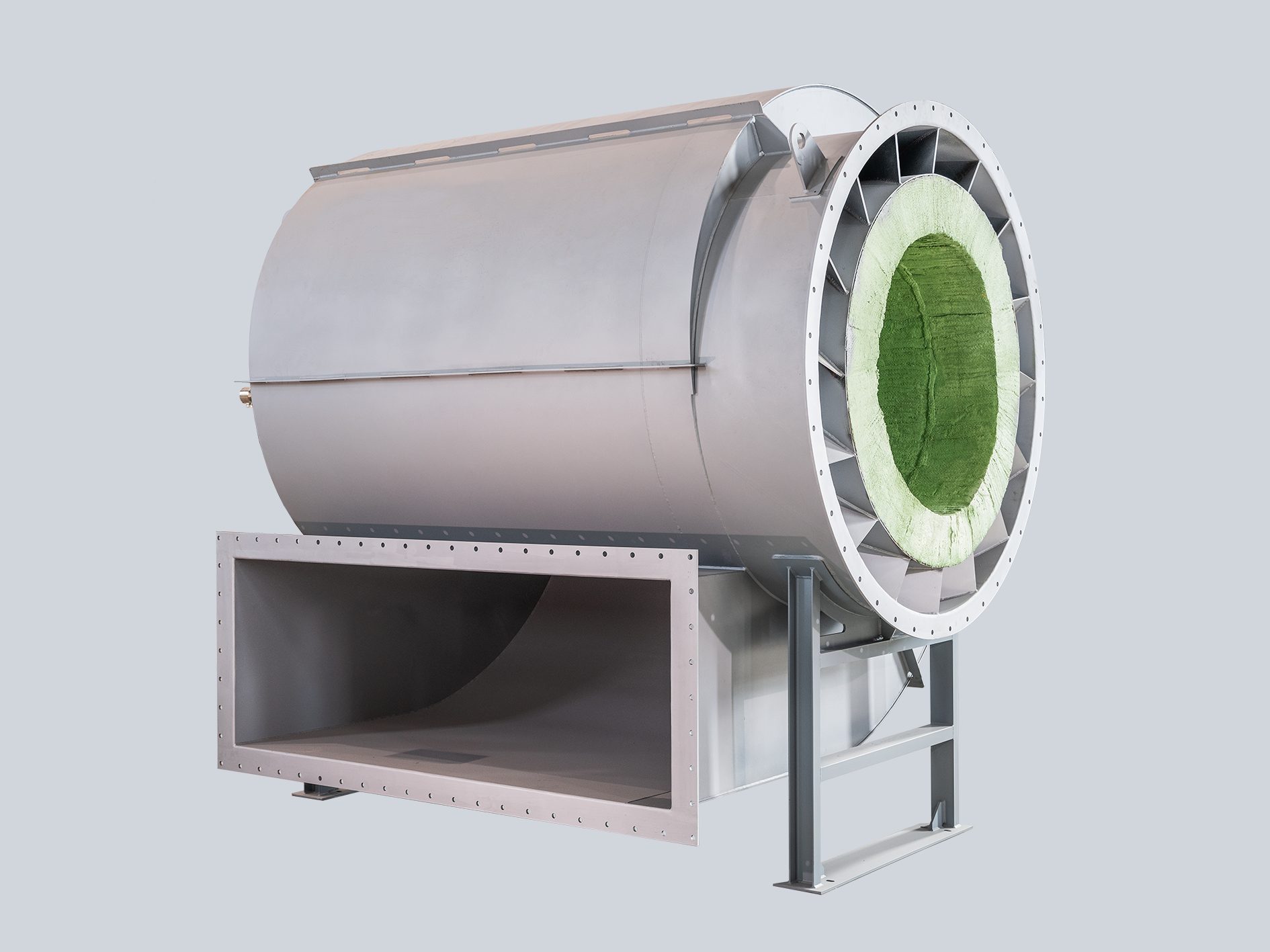

New Hot Gas Generator – the DUMAG® Swirl Preheater SPH Unit

A combination of Burner + Combustion chamber + Swirl device with high swirl effect + Homogenizer for direct heating of air or flue gases

The DUMAG® Swirl Preheater SPH is a cutting-edge solution for efficient and controlled heating of air or flue gases within a single integrated unit. Designed for applications such as hot gas generator for drying process for fluidized bed furnace, regenerative thermal oxidizers (RTOs) and combustion chambers for liquid or gaseous waste treatment, this technology ensures optimal performance in selective catalytic reduction (SCR) processes. The Swirl Preheater SPH unit heats the exhaust gas coming from the RTO to the temperature required for the selective catalytic reduction.

KEY features:

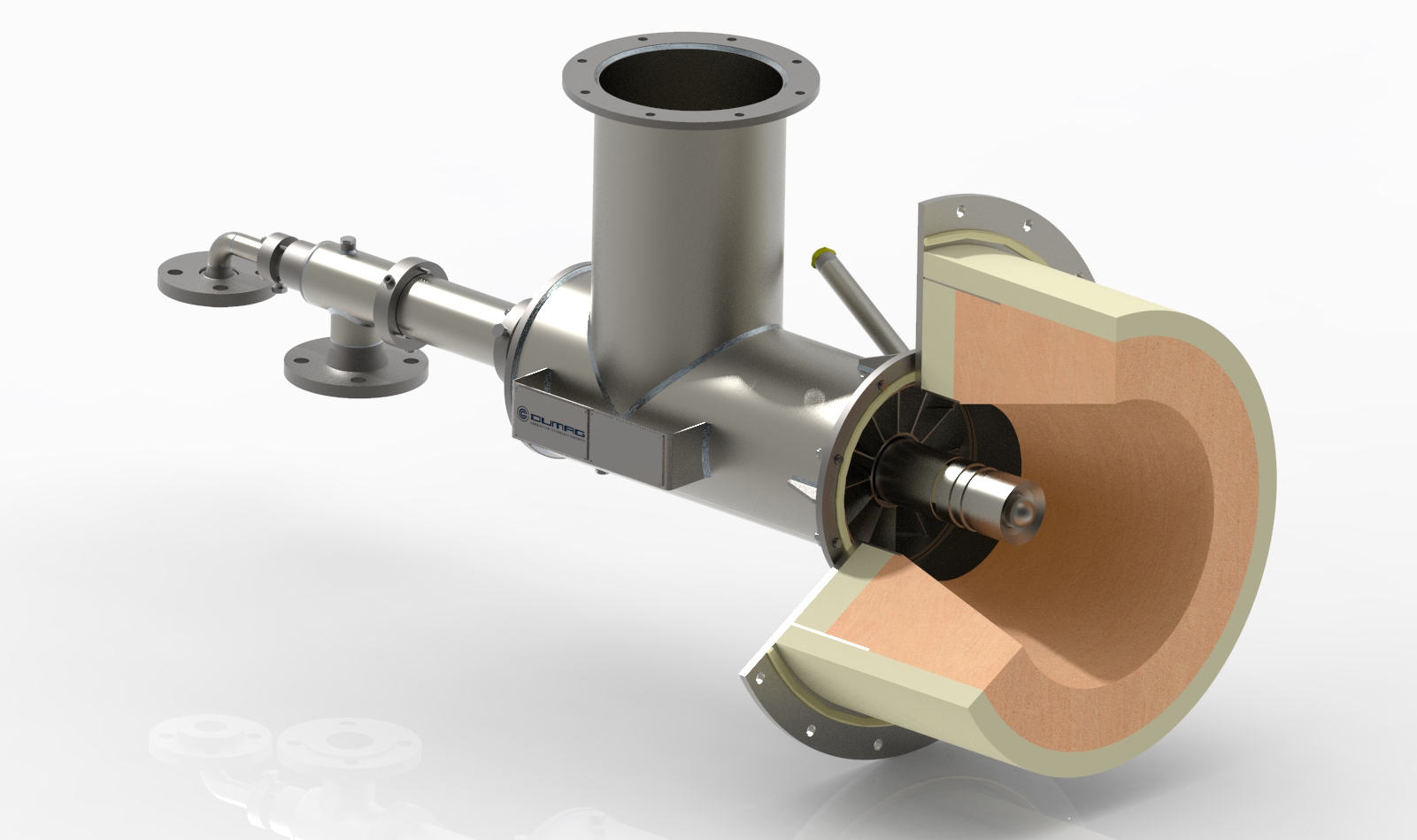

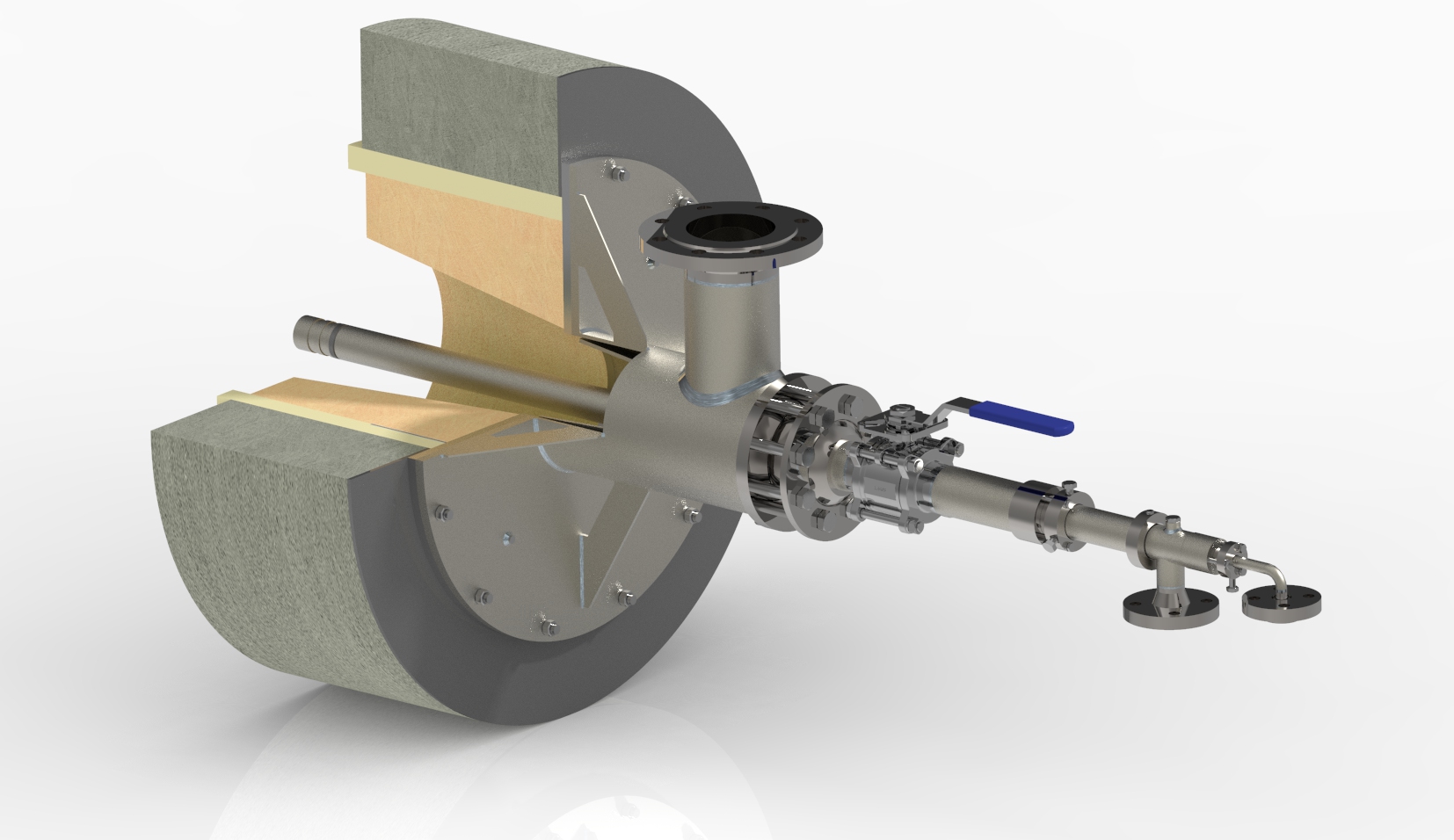

- Innovative system combining burner, combustion chamber, swirl device, and homogenizing section

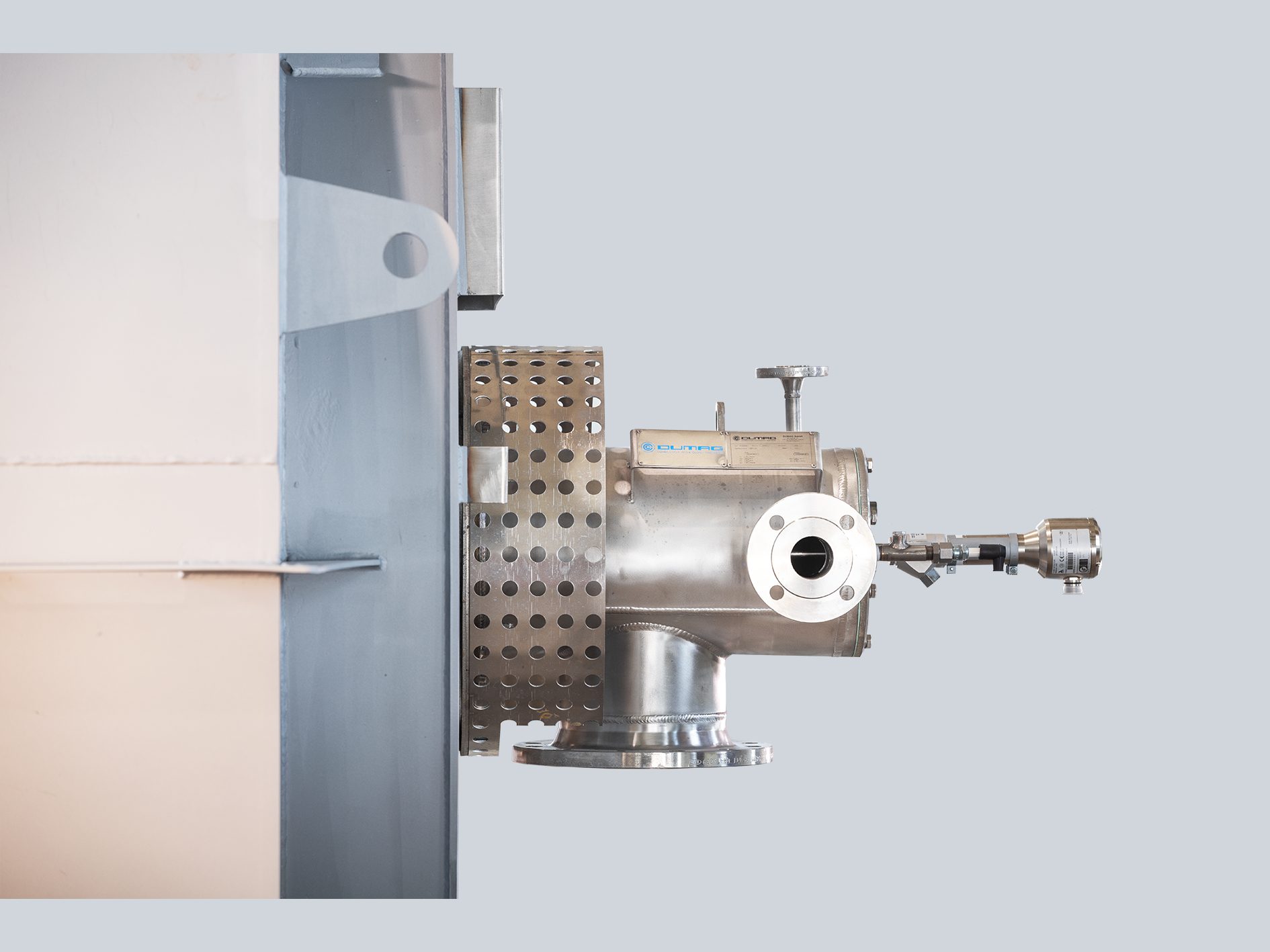

- Compact design, delivered as a complete unit

- Customizable solutions tailored to specific needs

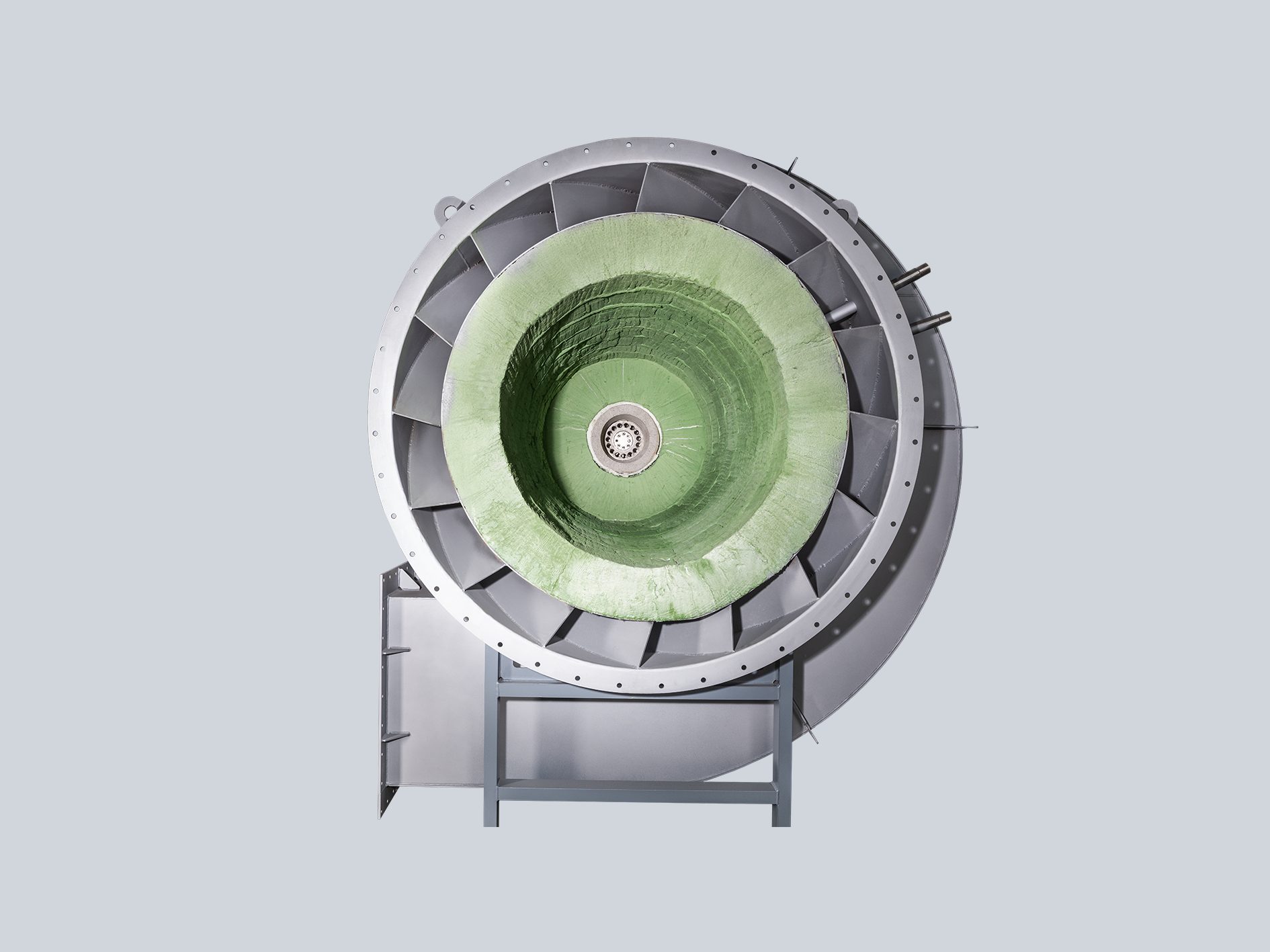

- Low pressure drop thanks to spiral inlet and individual calculations

- High swirl effect for improved mixing and homogeneity

- Suitable for various fuels including natural gas and light oil

- Available in different sizes and configuration

- Small footprint

perfoRmance characteristics:

- Uniform distribution of gas to be heated upon entering the swirl channel

- Reduced pressure losses through spiral arrangement

- Optimized homogenization as a result of extensive Computational Fluid Dynamics (CFD) studies

- Post-combustion gas temperatures around 1370–1450°C

- Ensuring proper operation of SCR systems

Quality Assurance

- Manufactured according to European and American standards, regulations, and quality certificates

- Tested and certified according to ISO9001

Are you interested in our technology? Then please contact us! We are pleased to provide you with further information.

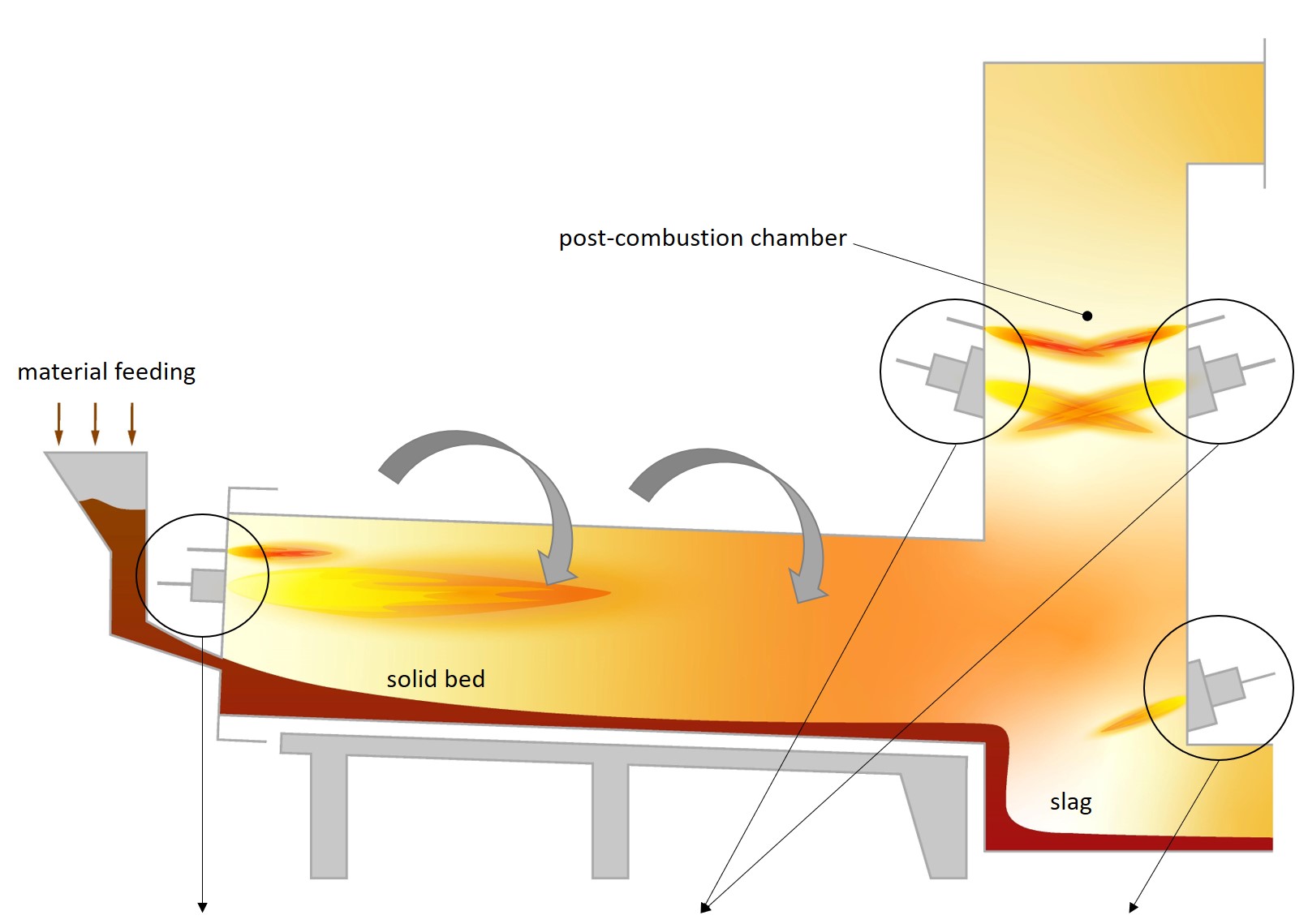

DUMAG® IB-rksc – integrated part of our burner package for rotary kilns

DUMAG has designed and built a great many customized burner systems for the installation in rotary kiln applications on a global basis. DUMAG burner equipment is specially designed for the treatment of industrial and hazardous waste in rotary kiln with post-combustion chamber. The all-round burner DUMAG IB-rksc features an individual swirl for flame length adjustment and the simultaneous operation of two or more gas and liquid fuel sources. The IB-rksc burner is a perfect fit for the installation in rotary kiln and post-combustion chamber supporting start-up and operation.

In addition to the all-round burner IB-rksc DUMAG offers supplementing auxiliary firing equipment including lance burner systems and various liquid and sludge injection devices which can be arranged expediently in the rotary kiln and the post-combustion chamber. Benefit from DUMAG’s experience and burner design capabilities for achieving a cost-effective and reliable operation of your rotary kiln treating industrial and hazardous waste.

Are you interested in our technology? Then please contact us! We are pleased to provide you with further information.