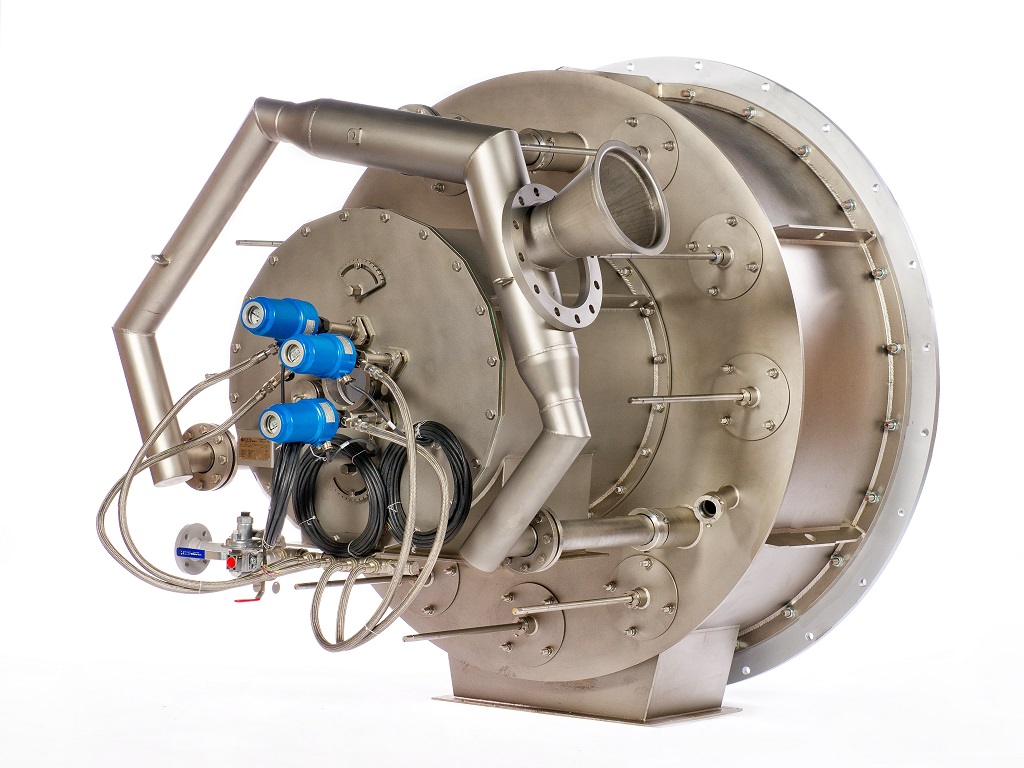

DUMAG® Industrial low NOx Burner IBX

Thanks to the special features of the DUMAG® IBX model, the burner system can significantly reduce thermal (temperature related) and fuel attributable (fuel bound nitrogen) NOx formation. A double or triple staged burner air supply, utilizing precisely positioned and directed lances, effectively reduces NOx combustion emissions.

Graduation leads to success!

The configuration of the burner also supports internal flue gas recirculation and staged fuel support, which results in further suppression of NOx formation. The burner design is flexible so our designers can adapt it for your application.

“We have brought NOx emissions under control. Staged air and fuel supply make it possible!”

Fullest customer satisfaction!

The DUMAG® LowNOx burner IBX is used in numerous industrial applications and provides low-emission thermal recovery of liquid and gaseous waste and side products. We are pleased to say that the low NOx model of the IB meets the expectations of our customers worldwide.

Key facts

- Individual design

- Combustion air temperature up to 400°C

- Control range up to 1:20

- Simultaneous combustion of standard and special fuels

- Minimizing operating costs through efficient technologies

Are you interested in our technology? Then please contact us! We are pleased to provide you with further information.

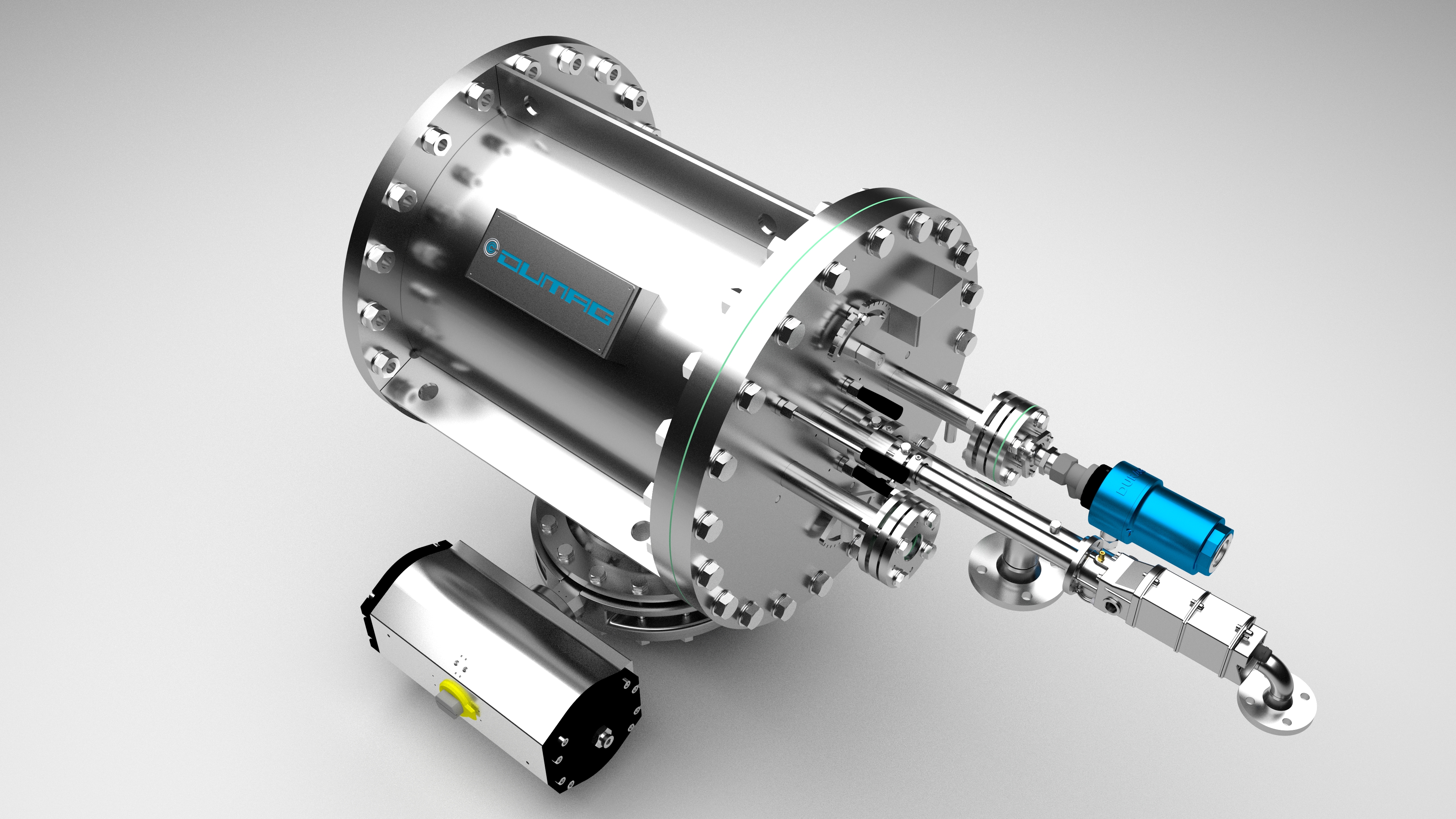

DUMAG® Industrial Burner IB

The IB (industrial burner) series is an incredibly versatile product in DUMAG’s portfolio and has proven itself as a reliable approach for a wide range of combustion applications as well as for processes with stringent NOx requirements. Indeed, the DUMAG IB burner has been the multipurpose solution for all kind of fluids – gases and/or liquids – or even high viscous slurries. Thanks to the ongoing process of optimization this burner has become a valued and preferred equipment for process technologies on a global basis.

Customized design

Starting from the requirements of the process application, nearly all parameters, including flame shape, length and swirl impact can be adjusted accordingly. Furthermore, the position of auxiliary devices, connections and even the block geometry are adaptable.

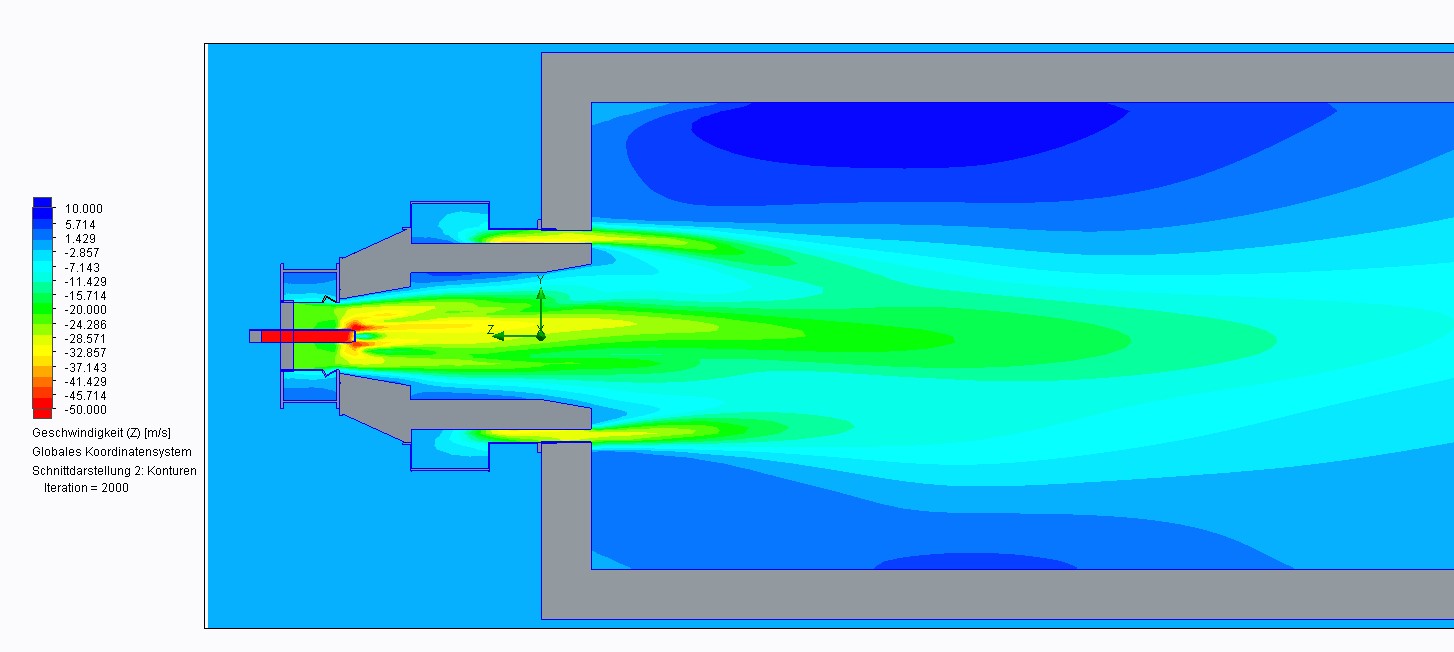

Illustrating the combustion process

DUMAG has extensive experience in the simulation of flow and mixture patterns resulting from various input streams, properties of burners/chambers or operation conditions. Especially when burning multiple fluid sources or considering a NOx sensitive application, CFD offers the possibility to review the design without the need for a pilot run, which minimizes the time and costs of implementation.

IBX – Low NOx plus high performance

Thanks to the special features of the IBX model, the burner system can significantly reduce thermal (temperature related) and fuel attributable (fuel bound Nitrogen) NOx formation. A double resp. triple staged burner air supply, utilizing precisely positioned and directed lances, effectively reduces the amount of NOx resulting from the combustion. The configuration of the burner also supports intern flue gas recirculation, which results into a further suppression of NOx formation.

Key facts

- More than 300 operating systems worldwide

- Burner sizes up to 150MW (MBtu/h)

- Turn-down range of up to 1:20 for gases and liquids

- Pressure-resistant design available

- Up to 8 different fluids (gases and liquids) can be introduced through the burner center

- Suitable for the use of special fuels (e.g. sulphur, sulphuric acid, etc.)

Are you interested in our technology? Then please contact us! We are pleased to provide you with further information.