DUMAG® Multifuel Burner MFB – MFBX and MFBSX

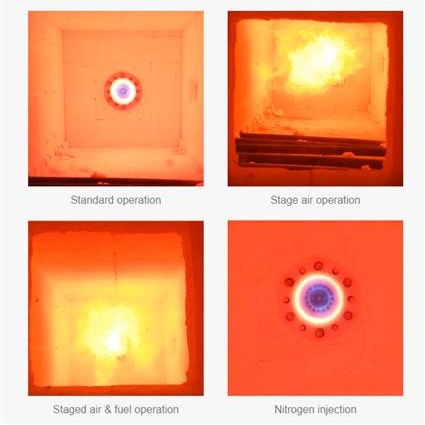

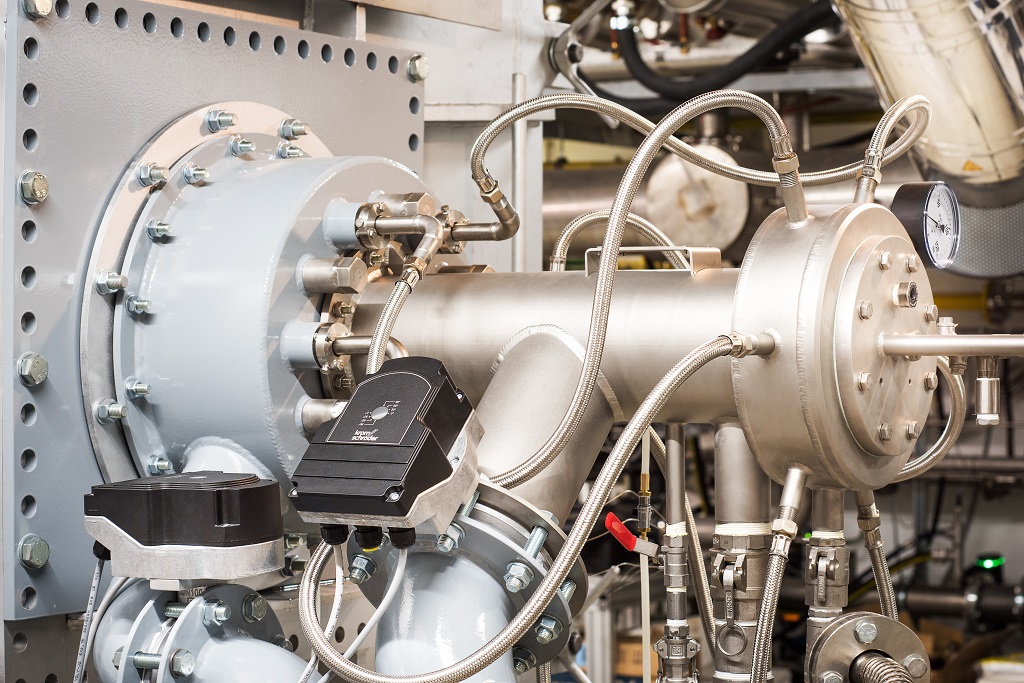

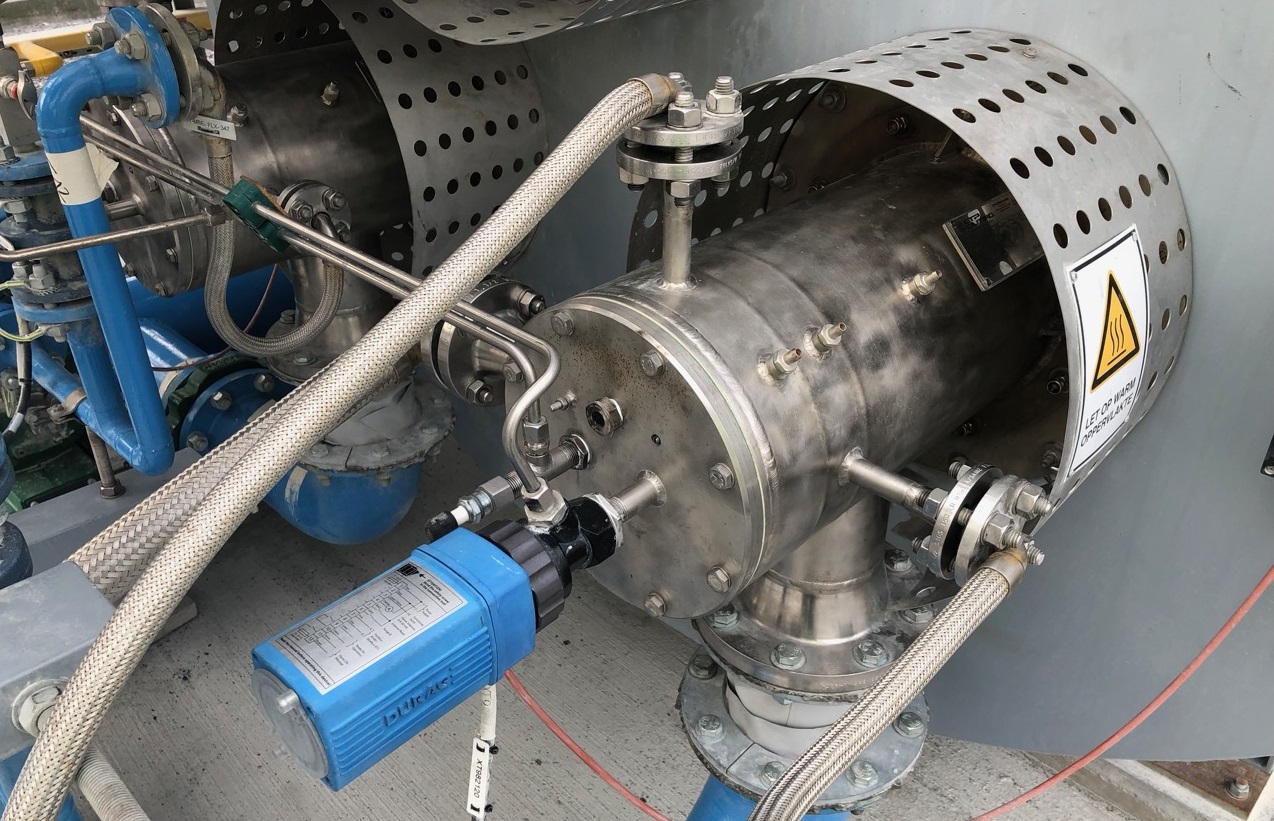

Whenever an application requires a stable firing process under demanding conditions achieving a very high turn down ratio, DUMAG’s multifuel burner might be the right answer. In order to meet the target for a cost-effective but still quality driven approach, the fully welded design of the MFB has been reduced to the essential though offering the possibility to operate with two kind of fuels. The sophisticated design allows for the combination of gas-gas or gas-liquid supply at an incredible turn-down ratio for both sources. For this and other sound reasons the MFB has developed to a bestseller in DUMAG’s portfolio.

The LowNOx upgrade

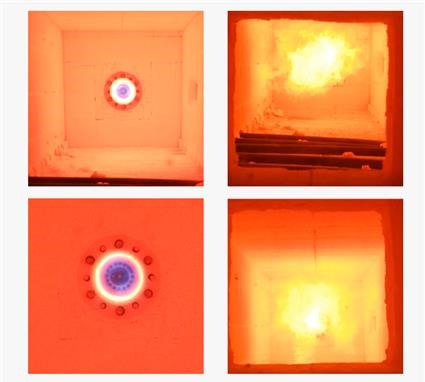

If an application requires measures to reduce the NOx to a minimum, the MFB can be upgraded to a LowNOx version MFBX by the means of a staged burner air introduction. Splitting the secondary air portion into partial flows, an internal recirculation can be achieved which inhibits the NOx formation.

When adding another air stage, the super LowNOx technology can also be achieved.

Description

The DUMAG©-LowNOx-Burner MFBX is a burner with double-staged conbustion air supply. The secondary air supply is bunched into three flows and creates inner flue gas recirculation. The combination of primary and secondary air and triple flow can be adjusted individually and this reduces NOx creation to a minimum. The burner is primarly used in themal oxidisers. Combustion air temperature may be pre-heated up to 200°C. Higher temperatures on request.

Typical applications

The MFB is used as a pilot or supporting burner, a single or dual fuel firing equipment or becomes an integrated part in a stand-alone process solution.

- Boilers

- Thermal Oxidizers (TO)

- Regenerative Thermal Oxidizers (RTO)

- Liquid fuel and waste incineration

- Air preheaters

- Hydrogen

Key facts

- Available from 100 to 4000 kW (350 to 13500 MBtu/h)

- Fully welded stainless steel design

- Demonstrable turn-down ratio of up to 1:30 for gas and 1:20 for liquids

- Ultrasonic technology applicable for liquid atomiziation

- Less critical spare parts

- High pressure and Ex-proof design available

- Meeting European and American standards

DUMAG® Multifuel Burner MFB

Whenever an application requires a stable firing process under demanding conditions achieving a very high turn down ratio, DUMAG’s multifuel burner might be the right answer. In order to meet the target for a cost-effective but still quality driven approach, the fully welded design of the MFB has been reduced to the essential though offering the possibility to operate with two kind of fuels. The sophisticated design allows for the combination of gas-gas or gas-liquid supply at an incredible turn-down ratio for both sources. For this and other sound reasons the MFB has developed to a bestseller in DUMAG’s portfolio.

The LowNOx upgrade

If an application requires measures to reduce the NOx to a minimum, the MFB can be upgraded to a LowNOx version MFBX by the means of a staged burner air introduction. Splitting the secondary air portion into partial flows, an internal recirculation can be achieved which inhibits the NOx formation.

Typical applications

The MFB is used as a pilot or supporting burner, a single or dual fuel firing equipment or becomes an integrated part in a stand-alone process solution.

- Boilers

- Thermal Oxidizers (TO)

- Regenerative Thermal Oxidizers (RTO)

- Liquid fuel and waste incineration

- Air preheaters

Key facts

- Available from 100 to 4000 kW (350 to 13500 MBtu/h)

- Fully welded stainless steel design

- Demonstrable turn-down ratio of up to 1:30 for gas and 1:20 for liquids

- Ultrasonic technology applicable for liquid atomiziation

- Less critical spare parts

- High pressure and Ex-proof design available

- Meeting European and American standards