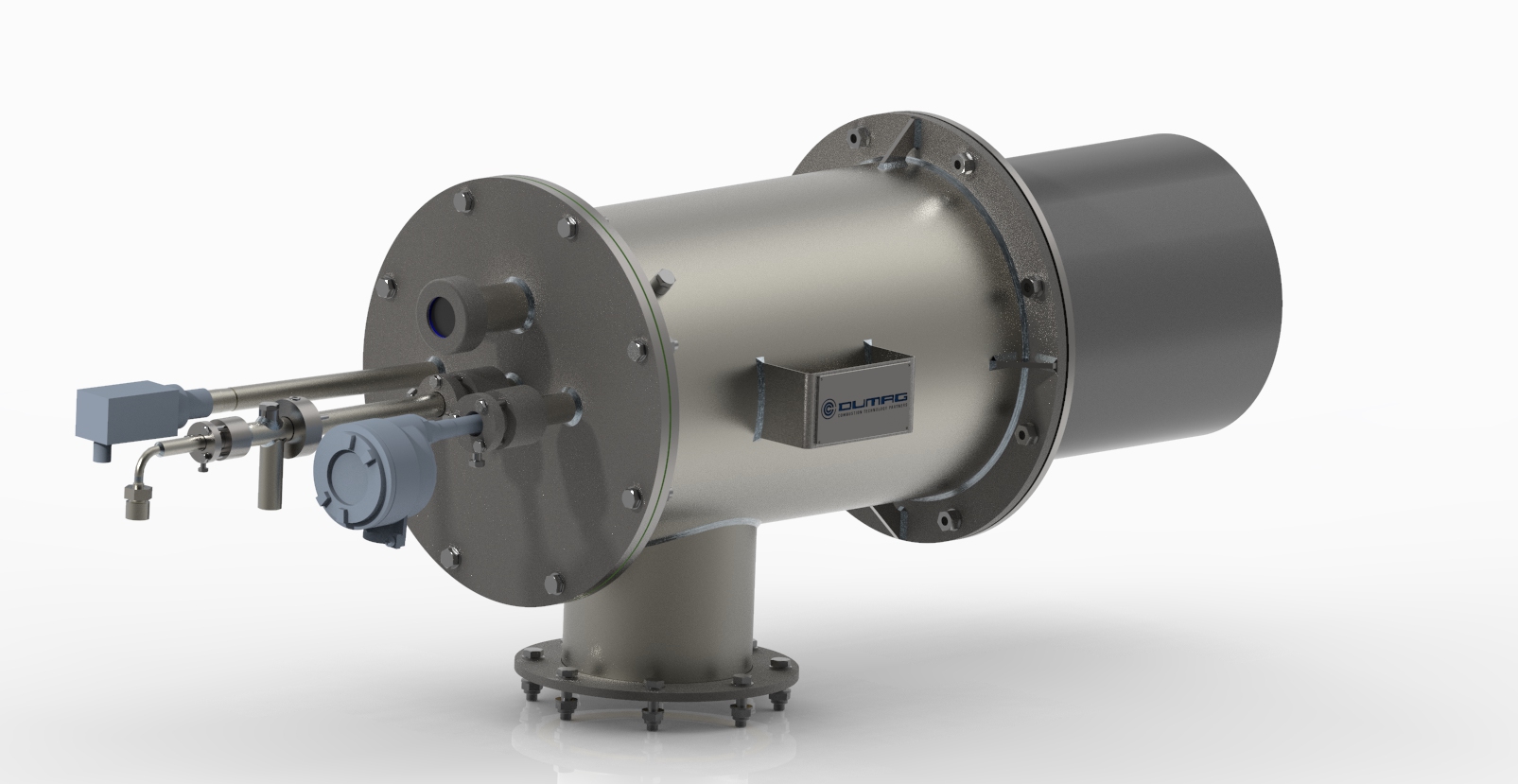

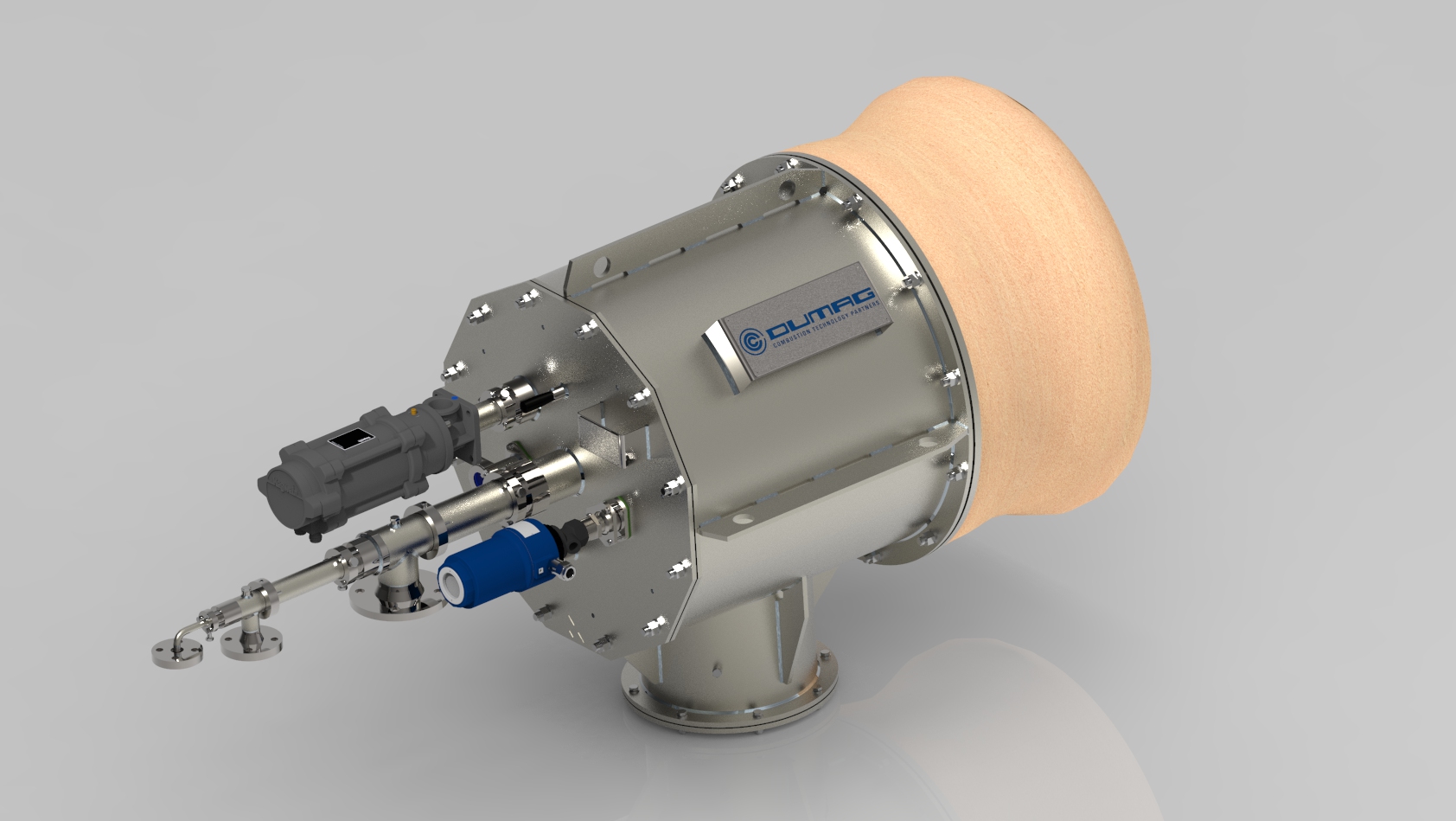

DUMAG® Process Burner PB

Burner for one or two types of fuel gas, fuel oil, exhaust gas, or waste liquid equipped with DUMAG® ultrasonic nozzles for gas or liquid for stable flames with a wide control range.

In the DUMAG process burner PB burner, lances with DUMAG ultrasonic nozzles in tulip shape are used for liquids or gases. Due to the flame stability when using these ultrasonic nozzles in the shape of a tulip – regardless of whether it relates to the atomization of liquids or a gas ultasonic nozzle – our engineers managed to develop a low-priced and very efficient burner.

By atomizing with compressed air or steam (liquid) or with 1.5 to 3 bar gas pressure, there is enough turbulence to ensure stability. The combustion air temperature is up to 200°C and depending on the fuels, the control range is from 1:5 to 1:10.

Field of applications:

- Boiler

- Combustion Chamber

- RTO

- Reformer

- Auxiliary burner in incinerators and many more

Structure

By simply replacing the flame former on the nozzle (ultrasonic nozzle for liquid or for gas), the lenght and diameter of the flame can be changed over a very wide range. The stability is always the same, regardless of whether the “flame former” is designed for short or long flames.

Due to the stability of the flame – given by the ultrasonic atomization and the turbulence of the atomizing medium – it makes it possible to design the burner housing very simple.

Are you interested in our technology? Then please contact us! We are pleased to provide you with further information.

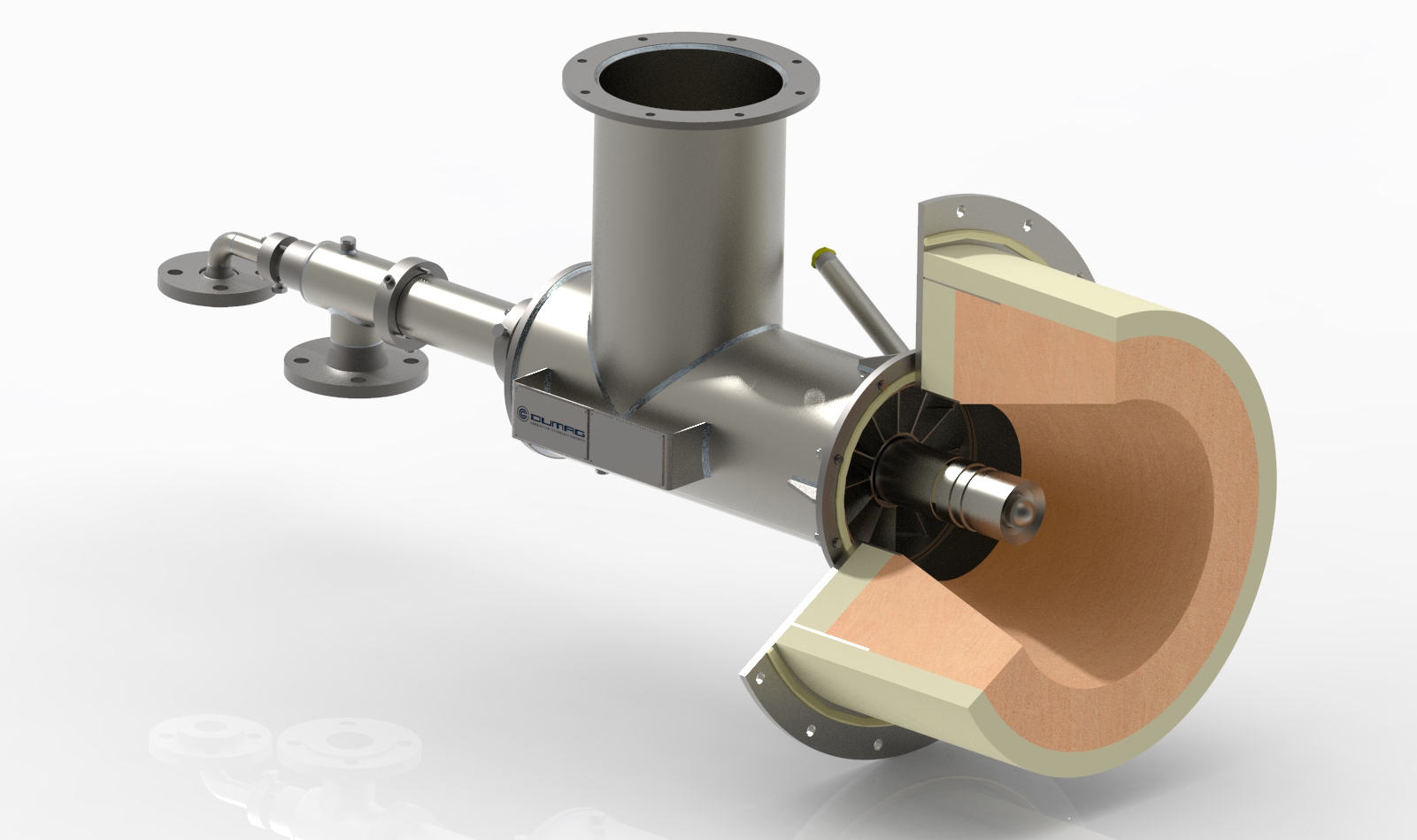

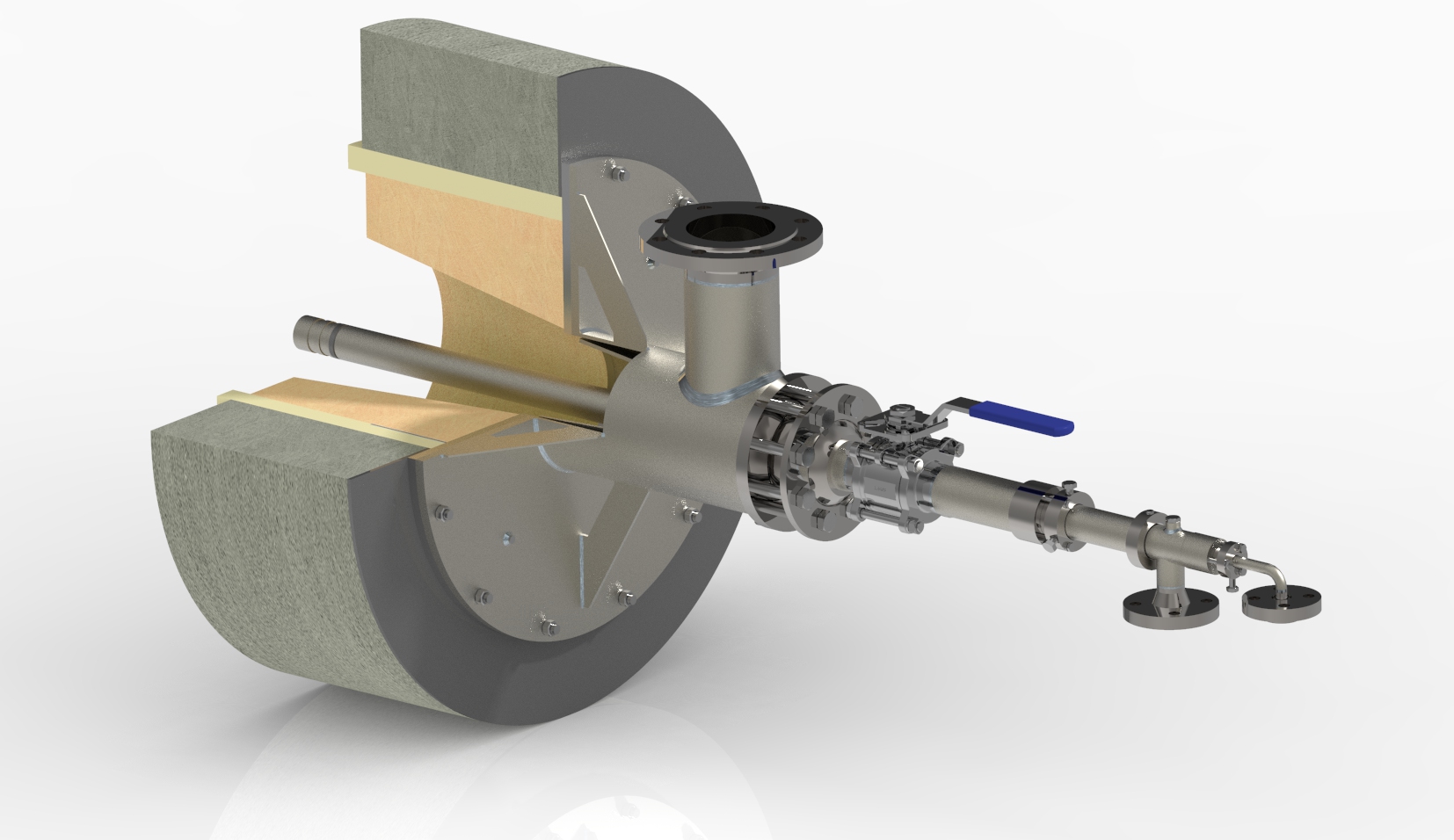

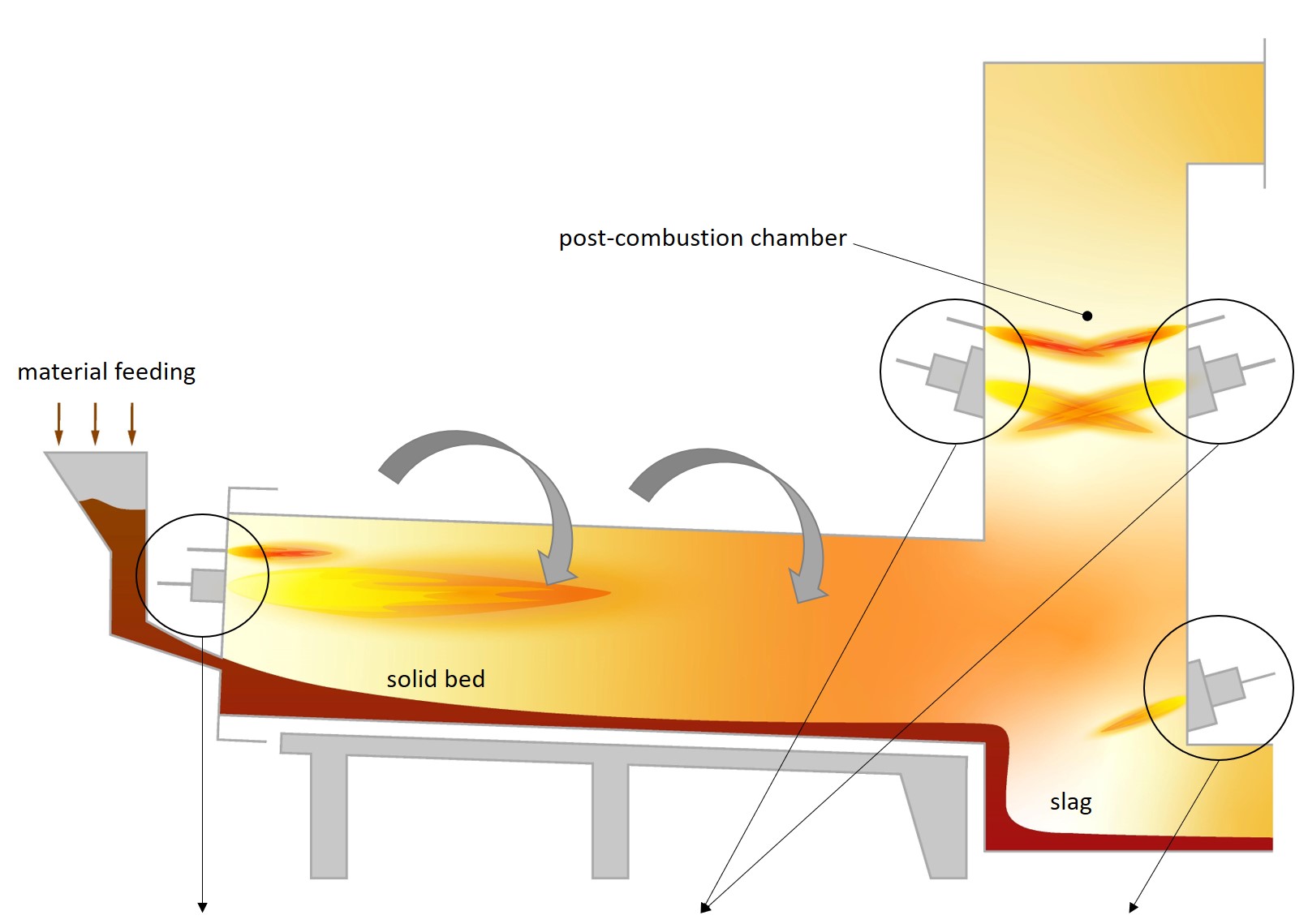

DUMAG® IB-rksc – integrated part of our burner package for rotary kilns

DUMAG has designed and built a great many customized burner systems for the installation in rotary kiln applications on a global basis. DUMAG burner equipment is specially designed for the treatment of industrial and hazardous waste in rotary kiln with post-combustion chamber. The all-round burner DUMAG IB-rksc features an individual swirl for flame length adjustment and the simultaneous operation of two or more gas and liquid fuel sources. The IB-rksc burner is a perfect fit for the installation in rotary kiln and post-combustion chamber supporting start-up and operation.

In addition to the all-round burner IB-rksc DUMAG offers supplementing auxiliary firing equipment including lance burner systems and various liquid and sludge injection devices which can be arranged expediently in the rotary kiln and the post-combustion chamber. Benefit from DUMAG’s experience and burner design capabilities for achieving a cost-effective and reliable operation of your rotary kiln treating industrial and hazardous waste.

Are you interested in our technology? Then please contact us! We are pleased to provide you with further information.